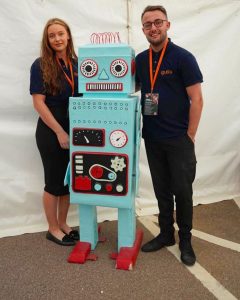

Last week we attended the RS STEMfest 2019 three day event.

Over the first two days, the igus® team welcomed groups of local school children and their teachers to the event and to the igus® stand. With over 500 students from primary and secondary education visiting the event RS Components did a fantastic job at engaging the kids. We welcomed the students into the exhibition area where we had our stand and everyone got to see the igus® robots in action as well as having a go on our NEW Virtual Reality headset where they got instantly transported to our head office in Cologne.

On the final day (Saturday 6th July) the event was open to the public and attracted over 800 visitors, with an amazing festival atmosphere, street food, and the RS Titan II truck taking centre stage in the exhibition area parents and guardians brought their children along and enjoyed seeing our robots, and finding out about igus® products.

Â

1. Efficiency: Vibrator sieves can handle large volumes of material quickly and efficiently, making them ideal for industrial applications where speed and capacity are crucial.

2. Versatility: They can be used for a wide range of materials, from powders and granules to liquids and semi-solids, depending on the design of the sieve and the application.

3. Ease of Use: They typically require minimal maintenance and are easy to operate. Some models are designed to be compact and portable, making them suitable for use in a variety of settings.

4. Customizability: Vibrator sieves can be customized to suit specific needs. This includes choosing the right mesh size for the material being processed, adjusting the vibration frequency and amplitude, and selecting the appropriate size and shape of the sieve for the task.

5. Safety: Modern models often include safety features such as automatic shut-off if the sieve door is opened during operation, and ergonomic designs to reduce operator strain.

Some industries that commonly use Vibrator Sieves include pharmaceuticals (for tablet and powder separation), food processing (for sorting and grading grains and spices), mining (for particle size reduction), and chemical manufacturing (for filtering and separating substances).

Vibrator Sieve,shale shaker screen producer,oilfield shaker screen mesh,oilfield shale shaker element

Hebei Yingkang Wire Mesh Product Co.Ltd , https://www.wiremesh-china.com