I.Introduction

In modern metal processing manufacturing, laser cutting technology serves as an indispensable process by virtue of its high quality, efficiency and wide material applicability. For potential consumers and enterprises, understanding the quality, features and applications of laser cutting machines in metal processing is crucial for improving product quality and minimizing production costs.

However, in the face of a dazzling array of laser cutters, customers commonly have difficulty in choosing the right one. Different types and brands of laser cutting machines vary greatly in performance parameters and prices. Therefore, it’s a dilemma for potential buyers to select the most appropriate one that meets their demands.

Thus, the article aims to provide the readers with an ultimate guide about the laser cutter comparison. I will compare the mainstream types of laser cutting machines in terms of cutting accuracy, cutting speed, material compatibility and cost-effectiveness.

It's important to know if the machines can meet the cutting requirements, which kind of machines are most effective, different laser cutters suit which material, and which types of laser cutting machines are mostly cost-effective when taking a holistic consideration of prices, using and maintenance costs.

Based on a deep analysis of the key factors in question, you can find the laser cutting machines that suit you. The guide will provide you with a thorough comparison and pragmatic and professional advice to mitigate obstacles in the journey of selecting laser cutting machines.

Let's kick off this ultimate showdown of laser cutting machines together!

II.Understanding Laser Cutting Technology

Basics of Laser Cutting

How does a laser cutting machine work?

Laser cutting machines utilize high-power density laser beams to irradiate the surface of the materials that are melted, evaporated, or burned to the ignition temperature. At the same time, assist gases are used to blow the melt off. In this way, the cutting was finished.

The procedures of laser cutting incorporate three steps: part heating, melting and melt blowing. The cutting technology, which is contactless, highly accurate and fast while cutting, is widely applied in the metal and non-metal processing industry.

What are the mainstream types of lasers used in cutting machines of markets? The article will provide you with three types of mainstream laser cutting machines: CO2 laser cutting machines, fiber laser cutting machines, and YAG solid laser cutting machines.

CO2 laser cutting machines:

CO2 laser cutting machines are mainly used in non-metal cutting, including wood, plastic, glass and fabric. With a wavelength of 10.6 micrometers, they are suitable for high-power output with energy conversion efficiency reaching 25% and, therefore, possess significant edges in non-metal cutting.

Fiber laser cutting machines:

Fiber laser cutting machines are famous for their high energy conversion efficiency, low maintenance costs and high-quality laser beams. With a wavelength of 1.06 micrometers and a high absorption rate for metals, they are suitable for metal cutting. Fiber laser cutters are good at cutting Stainless Steel, Carbon Steel and aluminium alloy.

YAG solid laser cutting machines:

As one of the early cutting technologies, YAG solid laser cutting machines are mainly used to cut metals. With a wavelength of 1.06 micrometers, YAG solid laser cutting machines are similar to fiber laser cutters.

However, limited by their cutting technology, YAG solid laser cutting machines are applied in a relatively narrower sphere and work at a lower efficiency.

Advantages of Laser Cutting Over Traditional Methods

Precision and quality of cuts:

Laser cutters allow for extremely high accuracy and high-quality cutting. Laser beams focused into a small light spot can cut intricate, small and delicate patterns with smooth cutting edges without burrs, reducing the subsequent need for processing.

Reduced waste and increased efficiency:

Thanks to their high accuracy, materials utilization can be optimized to the most so as to reduce waste materials. At the same time, laser cutting with high speed can improve productivity significantly, especially for batches of production, which can shrink the production cycle greatly.

Versatility in handling different materials:

In addition to handling metal, laser cutting technology can also handle various non-metal materials, such as plastic, wood and glass. Its versatility enables the technology to meet the demands of different industries and materials, widening the horizon of laser cutting technology applications.

III.Key Factors to Consider When Choosing a Laser Cutting Machine

Machine Types Comparison and Suitability

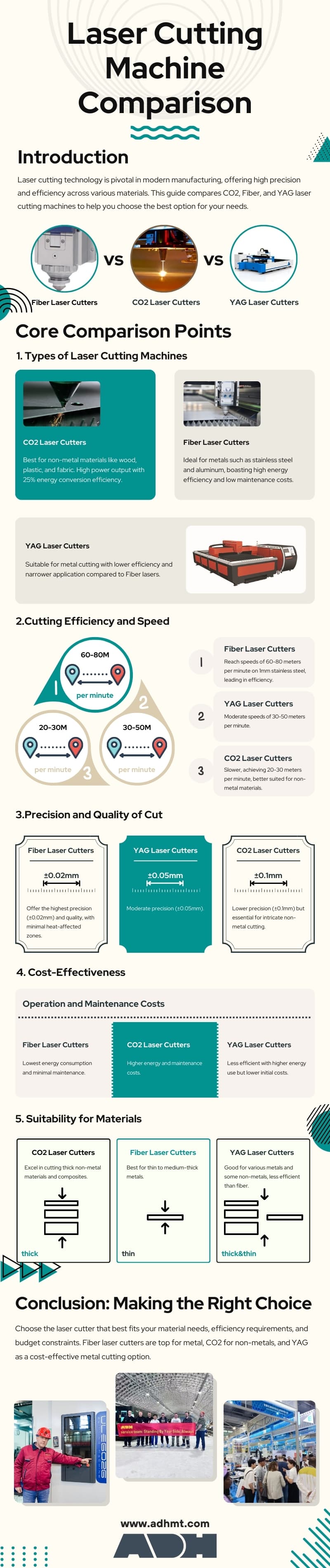

The three types of cutting machines have their own features in appliable materials, process performance and other aspects.

CO2 laser cutting machines, as one of the most common and widely used machines in the industry, are good at cutting. With larger power, they perform better in thich board material(over 10mm) cutting.

Fiber laser cutting machines utilizing fiber lasers are suitable for metal cutting, especially for high-speed and accurate cutting of thin metal sheets(such as materials within 1-8mm). Although weaker than CO2 laser cutting machines in terms of non-metal cutting, they are obviously better at cutting speed and cutting smoothness.

The YAG solid-state laser cutting machine uses a YAG crystal doped with neodymium ions as the working material with output wavelengths similar to fiber laser cutting machines. The beam quality of YAG laser cutting machines is between that of CO2 and fiber lasers, but their cutting speed and accuracy are not as good as those of fiber laser cutting machines.

All in all, in composite material cutting, CO2 laser cutters are the most wise choice. They are capable of cutting carbon fiber, glass fiber, and other reinforced composite materials, as well as difficult-to-machine materials such as ceramic matrix composites. But, if you seek for cutting quality and speed, fiber laser cutters are the top selection.

Cutting Speed and Efficiency

Cutting speed and efficiency are the main indicators for the measurement of productivity. Generally, fiber laser cutting machines generally have the highest cutting speed, followed by YAG laser cutting machines, while CO2 laser cutting machines are relatively slower.

Taking the cutting of a 1mm stainless steel plate as an example, high-power fiber laser cutting machines can reach 60 to 80 meters per minute, YAG laser cutting machines 30 to 50 meters per minute and CO2 laser cutting machines 20 to 30 meters per minutes.

High speed means a shorter processing cycle and higher productivity. For mass-produced metal workpieces, high-speed fiber laser cutting machines can significantly shorten the delivery period and reduce labor and machine costs. However, for small batches of production or non-metal cutting, CO2 laser cutting machines perform better.

Precision and Quality of Cut

Cutting precision as a key indicator of a laser cutting machine’s performance, directly decides the dimensional tolerance and surface quality of the workpiece.

In terms of cutting precision, fiber laser cutters are the best, then the YAG laser cutters and CO2 laser cutters the last, which are mainly decided by the quality of laser beams and the size of focused light spots.

The beam quality of fiber lasers approaches the diffraction limit, and the focused spot can be as small as 10-30μm, which results in narrower silts and small heat-affected zones with process accuracy reaching ±0.02mm.

YAG laser cutting machines’ beam quality is not as good as that of fiber laser cutters, with process accuracy reaching around ±0.05mm. Laser beam patterns and optical systems limit CO2 laser cutting machines with process accuracy reaching ±0.1mm.

The flatness and smoothness of the cut and the amount of burrs can also present cutting quality. The cutting quality of fiber laser cutters and YAG laser cutters is better than CO2 laser cutters because they produce more smooth cuts and fewer burrs.

Although CO2 laser cutting machines produce cuts with certain slopes and stripes and more burrs, they play an indispensable role in non-metal cutting.

Generally, for precise components and high-end decoration processing, which poses high requirements on size and appearance, higher processing quality can be offered by fiber laser cutters. For ordinary workpieces, YAG and CO2 laser cutting machines can also meet the basic requirements for quality and accuracy.

Therefore, consumers should balance the machines’ performance and costs based on product requirements in order to choose the most appropriate type of machine.

Cost of Operation and Maintenance

Operation and maintenance costs of a laser cutter are the main economic factors a user need to consider. These costs include energy consumption, consumable costs and maintenance and service costs.

When it comes to energy consumption, CO2 laser cutters consume the most, and then the YAG laser cutters and fiber laser cutters last. In long-term running, fiber laser cutters perform best.

Regarding consumable costs, the optical components, including laser gas, focusing lenses and protective lenses, of CO2 laser cutters need to be replaced regularly. While, fiber and YAG laser cutters have relatively fewer consumables. However, the intial investments of fiber laser cutters are higher than those of the other two types.

As for maintenance, the relatively intricate structures of CO2 laser cutting machines require professionals to calibrate the optical system and clean and wash the cooling system regularly.

All of these are easier for YAG and fiber laser cutters due to their compact structures and closed light paths. However, the repair costs of YAG and fiber cutters are higher than that of CO2 laser cutters.

Based on what I have discussed above, fiber laser cutters have the lowest operating costs because they consume the least energy, require fewer consumables, and require no maintenance.

If machine costs are taken into consideration, CO2 and YAG laser cutters have the edge over fibre lasers in medium and small power processing industries in terms of cost-effectiveness.

IV.Pros and Cons of Each Laser Cutter Type

At present, there are three mainstream types of laser cutting machines which include CO2 laser cutters, fiber laser cutters and YAG solid laser cutters. They have their own features, pros and cons, meeting demands for different processes.

Advantages and Disadvantages of CO2 Laser Cutters

CO2 laser cutting machines utilize CO2 lasers to cut with a wavelength of 10.6μm, suitable for cutting non-metals such as wood, plastic, glass, and paper.

Advantages:

Wide application: they can cut most non-metals with good cutting performance and smooth edges.

Fast speed: CO2 laser cutting machines can cut quickly for thin sheet materials.

High accuracy: They allow for precise cutting and suit intricate pattern processing.

Disadvantages:

High energy consumption: Low light and electricity conversion efficiency requires high energy consumption.

High maintenance costs: the maintenance costs for lasers and optical systems are high.

Unsuitable for metal cutting: they are not good at cutting metals, especially for highly-reflective metals.

Advantages and Disadvantages of Fiber Laser Cutters

Fiber laser cutters utilize fiber lasers with a wavelength of 1.06μm, mainly used for metal cutting.

Advantages:

High efficiency and energy save: they possess high light-electricity conversion efficiency and entail low energy consumption and operation costs.

High speed: they are faster than CO2 fiber laser cutting machines, especially for thin metal sheet cutting.

Low maintenance costs: basically, they are free from maintenance, thus possessing a long service life.

Disadvantages:

Limited in thick board cutting: they are slower while cutting relatively thick boards.

High costs: their initial investments are relatively high.

Unsuitable for non-metal cutting: their performance in non-metal cutting is not as good as that of CO2 laser cutting machines.

Advantages and Disadvantages of YAG Solid Laser Cutters

YAG laser cutting machines use solid-state lasers with a wavelength of 1.064μm, suitable for cutting metals and some non-metal materials.

Advantages:

Wide application: they can cut metals and some non-metal materials

Low costs: compared with fiber laser cutters, YAG laser cutters cost less

Simple operation: the simple structures entail relatively easy operation and convenient maintenance.

Disadvantages:

Low cutting efficiency: compared with fiber laser cutters, YAG laser cutters cut slower and less efficiently.

High energy consumption: with low light and electricity conversion rate, they consume more power.

High maintenance costs: lasers and optical systems entail regular maintenance, which increases costs.

Generally, different kinds of laser cutting machines have their own application sphere, pros and cons. When choosing laser cutting machines, you should take process demands, material types, costs and budgets into consideration in order to select out the most suitable one.

A table of comparison:

| Features/Model | Fiber laser cutting machine | CO2 laser cutting machine | YAG laser cutting machine |

| Laser wavelength | 1.06μm | 10.6μm | 1.06μm |

| Photoelectric conversion efficiency | About 30% | About 10% | About 3% |

| Cutting speed | High (4-5 times that of YAG) | Medium | Low |

| Maintenance costs | Low | High | Medium |

| Cutting material suitability | Mainly suitable for metal materials | Metal and non-metallic materials | Mainly suitable for metal materials |

| Cutting thickness | Suitable for thin to medium-thick plates | Suitable for thick plates and non-metallic materials | Suitable for thin plates |

| Cost of use | Low | High | Medium |

| Cutting quality | High (smoother cutting, less burrs) | Medium | Medium |

| Equipment price | High | Medium to High | Low |

| Ease of operation | High | Medium | Medium |

| Applicable industries | Sheet metal processing, aviation, aerospace, etc. | Advertising, model making, non-metal processing, etc. | Metal processing, decoration, advertising, etc. |

V.Innovations on the Horizon

The development and innovation of laser cutting machines play an essential role in improving productivity, lowering costs, and boosting manufacturing. As laser cutting technology develops, more new technologies will appear, profoundly impacting manufacturing.

Upcoming technological advancements

Higher efficiency and accuracy:

Advanced control technologies and high-precision movement systems have improved the processing accuracy and efficiency of laser cutters, enabling them to meet the demands of manufacturing better.

Flexible Production:

By introducing advanced flexible manufacturing technology, the machines allow for rapid adjustment and customized production, meeting personality demands.

More intelligent:

By introducing advanced machine learning and deep learning, they can implement adaptive control and intelligent optimization functions for devices to enhance their production efficiency and stability.

Green and environment friendly:

Adopting efficient cooling systems and low energy-consuming lasers lowers energy consumption and exhaust emissions, achieving green production.

Potential impact on the manufacturing industry

Improving productivity:

Accurate cutting reduces material waste and speeds up the production cycle, enabling enterprises to respond to the market quickly.

Lowering production costs:

Intelligent and automatic product methods lower labour and product costs.

Personalized production:

Flexible production of laser cutting machines empowers the manufacturing to meet the personalized demands of the market.

Promoting green production:

The green and environmental-friendly quality of laser cutting technology delivers a more green and sustainable future for the industry.

VI.Conclusion

As laser cutting technology develops and its application widens, laser cutting machines will fulfil their roles in manufacturing. Therefore, it’s important to understand the differences between the three types of machines so as to select the most appropriate one.

Ðs, a leading manufacturer of fiber laser cutters, ADH Machine Tool is always ready to equip you with all the knowledge you need to make the perfect choice. Feel free to contact us and our expert will answer all your questions.

Download the Infographic With High Resolution

Carbon Steel

Carbon Steel Seamless,Seamless Steel Pipes,Oil Tubing Pipe,Oil Well Tubing

Suzhou Yuhaoxuan Electromechanical Co., Ltd , https://www.essiont-pipeline.com